Diving into the world of 3D printing can feel like stepping into a sci-fi movie, but it’s more accessible than you might think. Whether you’re a hobbyist or a professional, choosing the right 3D printer can make all the difference in your projects. In this text, I’ll guide you through the key features to consider so you can make an well-informed choice.

From print quality to build volume and ease of use, there’s a lot to think about. I’ll break down the essentials, helping you understand what truly matters for your specific needs. By the end, you’ll know exactly what to look for to find the perfect 3D printer that fits your budget and goals.

Why is it Important to Choose the Right 3D Printer?

Picking the right 3D printer can save you time, money, and frustration. I remember buying a budget printer that struggled with PETG filament and often jammed. Investing in a quality machine avoided those headaches and improved my prints’ reliability and finish.

Consider how often you’ll use the printer and what materials you’ll print. A reliable printer will handle varied tasks with different filaments, including PETG, crucial for durable and heat-resistant prints. Your experience will be much more enjoyable, avoiding unnecessary headaches and downtime.

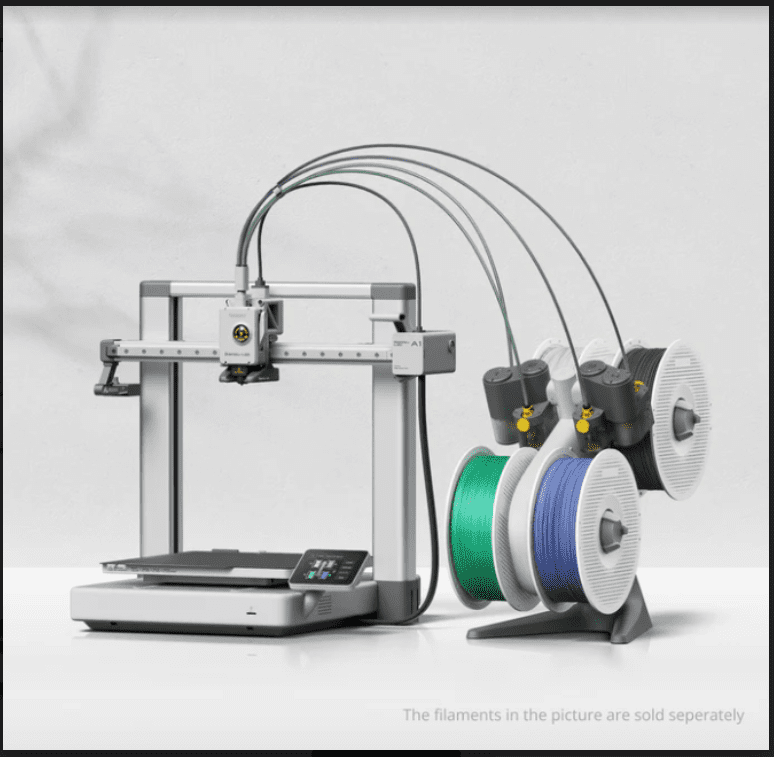

What Makes Printers from Bambu Lab Top-Notch?

Bambu Lab printers stand out for their impressive print quality and robust features. I used one for a complex project, and the results were phenomenal. The printer handled PETG filament without any issues, producing smooth, durable prints.

- High Precision: Bambu Lab printers deliver exceptional precision with layer resolutions as fine as 50 microns, ensuring highly detailed prints. This level of accuracy enhances the quality and intricacy of your 3D printing projects, producing professional-grade results.

- Large Build Volume: These printers are designed to handle large-scale projects, making them versatile and accommodating for various needs. Whether you’re working on complex prototypes or simple designs, their expansive build volume ensures flexibility and adaptability for any task.

- Ease of Use: The user interface is designed to be intuitive, making it accessible for both beginners and experts alike. Whether you’re just starting out or have years of experience, this interface ensures a smooth and efficient user experience.

- Versatile in Filament Handling: These printers are compatible with a wide range of filaments, including PETG, providing users with great flexibility. This versatility allows you to tackle diverse projects, from everyday prints to more durable, functional parts with ease.

Factors to Consider

When choosing a 3D printer, several factors influence performance and satisfaction. Considering the right elements can save both time and money.

Printer Type

FFF/FDM (Fused Filament Fabrication)

FFF/FDM printers use a spool of filament, typically PLA or ABS, which melts and is deposited layer by layer. They are user-friendly and suited for beginners. I started with an FDM printer and appreciated its simplicity for learning and experimentation.

SLA (Stereolithography)

SLA printers use a UV laser to cure liquid resin into solid layers. They offer higher precision and smoother surfaces. These printers are excellent for detailed projects and prototypes, though they can be messier and pricier than FDM.

Print Quality and Resolution

Layer Height and Nozzle Diameter

Layer height and nozzle diameter affect print detail and smoothness. Lower layer heights create finer resolution. For precise models, I use a 0.2mm nozzle for accuracy.

Printer Construction and Calibration

Sturdy construction and accurate calibration boost print quality. My prints improved dramatically after I meticulously calibrated the bed and ensured frame stability.

Print Volume and Build Area

Print volume dictates the size of objects you can create. For large projects, choose a printer with a bigger build area. My current printer has a 250mm x 210mm x 200mm build area, allowing me to print sizable prototypes in one go.

Material Compatibility

Common Materials (PLA, ABS, PETG)

PLA is easy to print, making it great for beginners. ABS suits more durable needs. PETG filament, a favorite of mine, offers a balance of strength and flexibility, ideal for functional parts.

Specialty Materials (TPU, Carbon Fiber, Nylon)

For advanced users, TPU offers flexibility and durability. Carbon fiber and nylon add strength and heat resistance. My friend’s carbon fiber parts have proven incredibly strong in practical applications.

Speed vs. Quality Trade-offs

Higher print speeds can reduce quality. When I rush a project, I notice rougher finishes and less detail. Slower speeds enhance quality, providing a polished final product. Balancing speed and quality based on project needs maximizes efficiency and results.

Conclusion

Selecting the right 3D printer’s crucial for achieving desired outcomes. My own experience with a budget printer struggling with PETG filament taught me the value of investing in quality. Look at key features like build volume, print quality, and material compatibility. Other significant factors include printer type, construction, and calibration. Making informed choices saves time, money, and frustration.

The New Jersey Digest is a new jersey magazine that has chronicled daily life in the Garden State for over 10 years.

- Staffhttps://thedigestonline.com/author/thedigeststaff/

- Staffhttps://thedigestonline.com/author/thedigeststaff/

- Staffhttps://thedigestonline.com/author/thedigeststaff/

- Staffhttps://thedigestonline.com/author/thedigeststaff/