Meat: Something a majority of Americans eat almost daily, but seldom think about the behind-the-scenes of.

It’s true, a large swath of meat-eaters want to indulge in the deliciousness without ever confronting the harsh reality of what’s on their plate. Meat comes from an animal—more specifically, one that was killed for your consumption. Due to farming practices in the U.S., the meat industry has become not only increasingly cruel, but also increasingly unsustainable. This is not to say that we shouldn’t enjoy meat, but we should think about it a bit deeper than we do.

Factory farming allows for large quantities of meat to be produced at the expense of quality and sustainability. Factory farms use up large chunks of land and require a shocking amount of fresh water to raise, feed and slaughter animals—20 percent of the world’s annual water usage is estimated to trace back to factory farming. Furthermore, because animals are not allowed to graze in these types of environments, a significant amount of water is spent on growing crops like soy, corn and other grains, which require upwards of 40 times more water than if animals could roam and feed naturally on grass and roughage. Farming in this style massacres our water supply and the climate.

Still, many turn to these foods because they’re simply more accessible. Even in a state as dense in farmland as New Jersey, it is still difficult to find high-quality meat if you aren’t seeking it out. Changing our habits surrounding meat isn’t just morally right—it’s a necessity.

It’s about taste too. Farm-raised chicken has real flavor to it as opposed to much of the water-packed, bland mess you’ll find in grocery stores, and good pork eats worlds better than the factory-farmed stuff. There is simply not a cut of factory-farmed meat in the world that tastes better than the meat from a responsibly raised animal—that’s the truth.

So, I went on a journey to find a New Jersey butcher shop that cared about these same things. One that I could purchase meat from without a guilty conscience. One that preaches the practice of using the entirety of the animal, from the nose to the tail. And, perhaps most importantly, one that just delivers a product that tastes better and is better for you.

My research led me to Palmer’s Quality Meats in Neptune City, NJ and with it, came a discovery of what might just be one of New Jersey’s finest butchers.

Palmer’s Quality Meats is a whole animal, sustainable butcher shop and brainchild of husband and wife duo, Doug and Joelle Palmer. Upon walking through the doors, I was in my own version of Heaven: Cases filled with housemade sausage, guanciale and hard-to-find cuts of meat. Each and every ingredient thoughtfully sourced from local farms and purveyors. Only seven months in business and they are properly busy—a good sign that this style of shop is what the masses crave.

Doug, who is also the head butcher, made it clear to me from the jump that Palmer’s was more than just the product of his ingenuity and skill. Instead, it was a collaborative effort, fueled by a team of talented individuals.

“We are nothing without our team,” Palmer told me. And as I zoomed out, the vision came into focus. That’s because Palmer’s Quality Meats is dedicated to their concept, one that revolves around high-quality meat, sourced in an ethical fashion. To achieve this is no easy feat. It requires sourcing from only the best farms, finding slaughterhouses that are morally identical to your vision and perhaps most importantly, employing a team who is passionate about the same things you are.

Let’s back up a bit, though. Doug Palmer didn’t just wake up seven months ago and decide to open a butcher shop—this was years in the making. It all started when he left his career in commercial diving and moved into butchery. He was leading a team in the butcher department at Whole Foods.

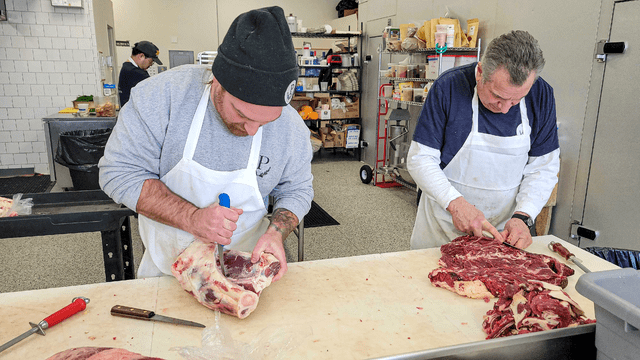

“It’s the best job ever,” he told me, “I get to cut meat all day.” And it was there where he met who would eventually become a big part of the larger vision, Armando Ferrante, who has been cutting meat for the larger part of 50 years. Doug honed his craft over the next several years, even working at a cattle company after Whole Foods where he learned the ins and outs of what goes into animal agriculture—from feed to slaughter.

When it came time to plan for the future, Palmer knew owning a shop was what he wanted, but he had some boxes he had to check off if he was going to be successful: Whole animal butchery, a kitchen aspect (and a chef to run it), a team that was bursting at the seams with both skill and knowledge and of course, a well-equipped space to run the show. Ferrante, who longed for whole animal butchery, was eager to join Palmer in the operation. Doug explained to me that the space Palmer’s resides in was built entirely from scratch.

“This building was empty; there were dirt floors,” Palmer stated, “I was able to design the space exactly how I wanted to. It was perfect,” he continued.

In true butcher’s fashion, the space is anatomically perfect. Frozen meats, prepared goods, stocks, farm fresh eggs from Skeleton Hill Farms, Jersey Girl Cheese and more can be found at the front of the shop, an amply-stocked meat case is dead center, and the butcher’s block in plain sight behind it, so that guests can sneak a glimpse at the inner workings of craft butchery. It is clean and sleekly done, making for a truly comfortable experience for the customer.

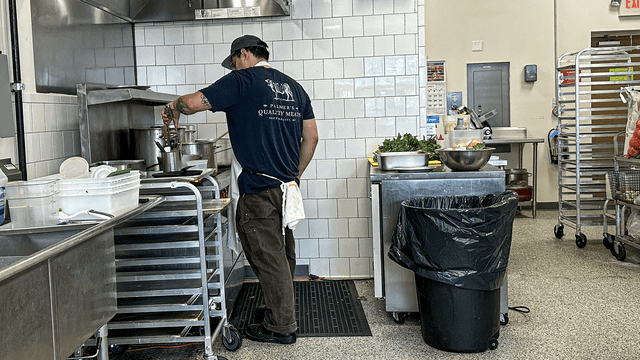

In the back left corner of Palmer’s Quality Meats is the kitchen. This is where much of the magic happens. Doug and Joelle Palmer already knew when opening that they wanted a well-trained chef so that they could put forth a more complex menu for guests. That’s where Chuck Cruz comes in, Head Chef of Palmer’s Quality Meats. Chuck’s resume is quite decorated, including culinary school training, several years cooking in restaurants and recipe development work. At Palmer’s, he has the freedom to employ multiple facets of his many years of experience as he sees fit.

This means making perfect stocks and broths daily, sausage making and what will no doubt put Palmer’s on the map, their already legendary sandwiches. Thursday through Saturday is when sandwiches are available and they sell fast. Each week, Cruz and the team come up with two unique sandwiches to sell into the weekend and it seems that he continues to outdo himself with each new creation. This could mean anything from cheesesteaks and chicken parms to lamb kofta pitas and Chicago-style hot beef sandwiches—piled high with house-made giardiniera and doused in luscious beef jus. The best part? Each sandwich is made with the same high quality meat that is sold in the case.

“We don’t waste anything,” Palmer stated, “having someone like Chuck on the team makes that possible.”

In addition to sandwiches, meat pies and empanadas are sold—made by Palmer’s resident baker, Megan Jacobson. The meat pies are made with a classic, lard-based pie dough. Hog scraps are rendered down into pure lard which can then see a second use. Another set of proof that this shop is a true display of team excellence.

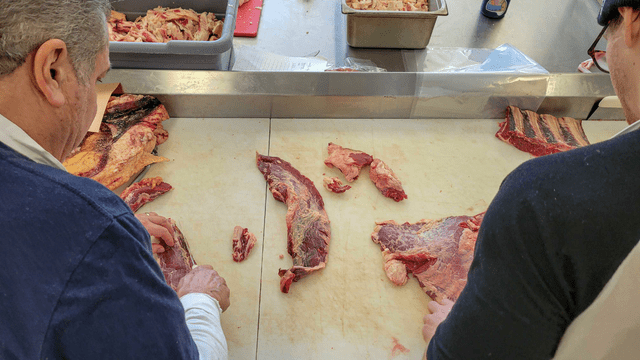

As I was touring the shop, I noticed Ferrante teaching a young butcher how to break down a beef hind quarter. Palmer explained to me that that was their apprentice, Peter Squassi, who came to Palmer and asked to learn. Of course, he was warmly welcomed and through Palmer and Ferrante, he is learning butchery from the best.

“I met Pete at a restaurant he was working at.. he got bit by the butcher’s bug and told me he’d work for free if it meant he could learn,” Palmer explained to me, “I told him better yet, I’ll pay you to learn.”

This is admirable in the industry and through it, Palmer and Ferrante are teaching a valuable skill that is more important now than ever to preserve our animal agriculture.

With this incredible team, Doug and Joelle Palmer’s vision has literally come to life. Skill is found in every corner of Palmer’s Quality Meats and it shows in the product. Speaking of products, they offer a truly remarkable selection of items.

100 percent grass-fed beef. Doug explained to me how they offer both grain-finished and grass-finished cuts of beef as the flavor differs between the two. Before being broken down, the beef is allowed to dry age for a minimum of 14 days to improve flavor and texture. Some subprimals of beef—like the short loin—are allowed to age even longer to produce a more aged steak or chop. American Lamb, chicken, pork and more are also available daily.

Because Palmer’s utilizes whole-animal practices, custom orders are a large chunk of their business. Breaking a whole animal down allows for it to become their canvas. In other words, they can create different, more unique cuts by breaking down the animal in different ways. So, if there’s a cut you can’t seem to find anywhere, or if you just want something oddly specific, give them a call and they’ll be happy to oblige.

Beyond the actual cuts of meat, some of the most enticing products in the case are meatballs and sausage. The meatballs being a classic Italian-American recipe that can be bought alongside a homemade, jarred tomato sauce. The sausage is cased in house and contains a secret ingredient: Gelatinous stock. That’s right, Chef Cruz makes a very concentrated pork bone broth that solidifies when cooled down due to naturally occurring gelatin in animal bones. Then, they finely dice this jello-like broth and add it to the sausage meat. When the sausage is cooked, this liquifies and creates a juicy and well-flavored link. Palmer’s Quality Meats offers several varieties of sausage including parsley and cheese, chorizo, Thai pork, among others.

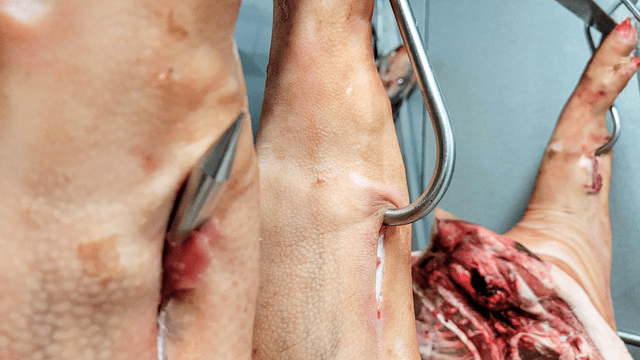

What becomes abundantly clear, even after spending thirty seconds in the shop, is that at Palmer’s Quality Meats, no piece of the animal is wasted. This is often referred to as nose-to-tail butchery in the industry and Doug Palmer takes this idea utterly seriously. Pork cheeks make guanciale, trim goes to sausage, organ meat gets blended with chuck meat to create a health-packed blend of ground beef, bones go to Cruz’s station to become stock—if it has a use, it’s getting saved.

This is not only lucrative, but it means that in the long run, less animals are used for the operation. Because they are getting more out of each animal (and because they have the skill to do it), Palmer’s can contribute to sustainability while still delivering a catalog of excellent products. This is the model that must be adapted across the globe to preserve our climate and to reduce cruelty within the meat industry. At Palmer’s Quality Meats, they even go as far as to save bone scraps from the shop’s bone saw and send them back to the farms to use as chicken feed. This is just one more example of how Palmer’s is the antithesis of waste.

It is shops like Palmer’s that give me hope for the future of food—both in New Jersey and across the country. Artisan butchery, which was once a necessary and respected profession, has sadly died out over the years. People like Doug Palmer and Armando Ferrante are working to revive it, though. Beyond the health and environmental factors of ethically sourced meat, it also simply tastes better. Once you become acquainted with high-quality meats, it is difficult to ever look at the mass-produced, hormone-injected stuff the same.

Palmer’s Quality Meats has laid the groundwork for the fate of what butchery must become. With any luck, aspiring butchers will follow in Doug Palmer’s footsteps and we can one day make it back to a world where ethically sourced meat is the norm. At the very least, our environment and palates will thank us.

Peter Candia is the Food + Drink Editor at New Jersey Digest. A graduate of The Culinary Institute of America, Peter found a passion for writing midway through school and never looked back. He is a former line cook, server and bartender at top-rated restaurants in the tri-state area. In addition to food, Peter enjoys politics, music, sports and anything New Jersey.

- Peter Candiahttps://thedigestonline.com/author/petercandia/

- Peter Candiahttps://thedigestonline.com/author/petercandia/

- Peter Candiahttps://thedigestonline.com/author/petercandia/

- Peter Candiahttps://thedigestonline.com/author/petercandia/